Stuff Interchangeable SAE Split Flange 3000 Psi 6000psi Socket Weld Flange

Description

Basic Info.

| Model NO. | steel flanges |

| Manufacturing Way | Forging |

| Transport Package | Fit for Sea Shipment |

| Origin | Hebei China |

| Production Capacity | 10000 |

Product Description

Socket Weld Flanges

Socket weld flange simplified as SW flange, it has a recessed area (like a shoulder) in the flange bore, this shoulder serves as a guide to set the depth of the pipe that inserted to the flange.

Standard:

Carbon steel ASTM A105, ASTM A350 LF1/2, ASTM A181

Alloy steel ASTM A182 F5, F9, F11, F22, F91

Stainless steel ASTM A182 F304/L, F316/L

Outer Diameters: 1/2 inch to 24 inch, up to 2500#

Special made: 24'' to 60'', up to 900#

Wall Thickness: Schedule 40 to 160

Pressure Ratings: Class 150 to Class 2500

Face Type: RF, RTJ

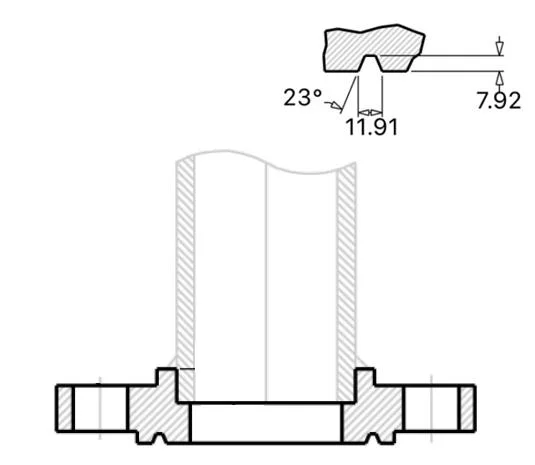

The socket welding flange is similar to a slip-on flange except it has a bore and a counterbore dimension.

The counterbore is slightly larger than the O.D. of the matching pipe, allowing the pipe to be inserted into the flange similar to a slip-on flange.

The diamter of the smaller bore is the same as the I.D. of the matchine pipe A restriction is built into the bottom of the bore which sets as a shoulder for the pipe to rest on

Socket Welded Flange Face Types

Socket welded flange inlcuding RF type and RTJ type, which like other types of welding flanges (slip on, weld neck or blind flange).

RTJ Type

On the raised face surface there has a groove is RTJ type, which you can place a gasket ring to get better sealing performances.

Advantages

- Socket weld flange could replace threaded flange, to minimize the risky of leakage.

- No need to beveling before welding.

- Welding work outside of the pipe, will not penetrate the pipe bore

- It is recommended for applications where internal welding operations are particularly difficult. This sock welded construction eliminates internal pockets while avoiding warpage of welding heat and damage to the flange face caused by weld spatter. It has the same internal pressure as the sliding on the flange, and has a better fatigue life.

Disadvantages:

- Socket welded flange requires higher skills for welder, which the welding need to make sure that the expanding gap between the pipe and shoulder is 1/16 inch.

- The expansion gap create the chances for the crack defects, especially for anti corrosive pipes as stainless steel pipes, so the cracks between the pipe and flange will cause the corrosive problems. So SW flange will not be compatible with corrosive or radioactive environment, as this solid buildup at the joint can cause operational and maintenance problems. So that's why people use but welding more often as the welding completely through the pipe from outside to inside, which makes the connects more strong and anti corrosive.

Socket Weld Flange vs Slip On Flange

Socket welded flange shape is similar to slip on flange, differently it has a shoulder at the inner bore.

Socket weld flange static strength is equal to slip on flange, but it's fatigue strength is 50% higher than the double welded slip on flange.

Referred Standard and Grades

- ASTM A105 for carbon steel slip on pipe flanges.

- ASTM A182 for alloy and stainless slip on flanges. (Alloy for F11, F22, stainless for F304/F304L, F316/F316L)

- ASME B16.5 for pipe flanges and flanged fittings.

- BS 3293

- DIN 86029

Socket weld flange datasheets

| Class | Raised Face |

| ANSI 150 | Socket, ANSI Class 150 (in) |

| ANSI 300 | Socket, ANSI Class 300 (in) |

| ANSI 400 | Socket, ANSI Class 400 (in) |

| ANSI 600 | Socket, ANSI Class 600 (in) |

| ANSI 900 | Socket, ANSI Class 900 (in) |

| ANSI 1500 | Socket, ANSI Class 1500 (in) |

| ANSI 2500 | Socket, ANSI Class 2500 (in) |

Uses of socket weld flanges

- They are ideal for small diameter applications.

- They are used for high pressure applications.

- Socket weld flanges have an internal recess on the inside diameter which allow for a smoot flow of the process fluid.

- They create a smooth bore with the proper welding and grinding.

Materials

Pipe flanges are manufactured in all the different materials like stainless steel, cast iron, aluminium, brass, bronze, plastic etc. but the most used material is forged carbon steel and have machined surfaces.

Flanges are welded to pipe and equipment nozzle. Accordingly, it is manufactured from the following materials;

- Carbon steel

- Low alloy steel

- Stainless steel

- Combination of Exotic materials (Stub) and other backing materials

The list of materials used in manufacturing is covered in ASME B16.5 & B16.47.

- ASME B16.5 -Pipe Flanges and Flanged Fittings NPS ½" to 24"

- ASME B16.47 -Large Diameter Steel Flanges NPS 26" to 60"

Commonly used Forged material grads are

- Carbon Steel: - ASTM A105, ASTM A350 LF1/2, ASTM A181

- Alloy Steel: - ASTM A182F1 /F2 /F5 /F7 /F9 /F11 /F12 /F22

- Stainless Steel: - ASTM A182F6 /F304 /F304L /F316 /F316L/ F321/F347/F348

Frequently used astm grades

| Material | Fittings | Flanges | Valves | Bolts & Nuts |

| Carbon Steel | A234 Gr WPA | A105 | A216 Gr WCB | A193 Gr B7 A194 Gr 2H |

| A234 Gr WPB | A105 | A216 Gr WCB | ||

| A234 Gr WPC | A105 | A216 Gr WCB | ||

| Carbon Steel Alloy High-Temp | A234 Gr WP1 | A182 Gr F1 | A217 Gr WC1 | A193 Gr B7 A194 Gr 2H |

| A234 Gr WP11 | A182 Gr F11 | A217 Gr WC6 | ||

| A234 Gr WP12 | A182 Gr F12 | A217 Gr WC6 | ||

| A234 Gr WP22 | A182 Gr F22 | A217 Gr WC9 | ||

| A234 Gr WP5 | A182 Gr F5 | A217 Gr C5 | ||

| A234 Gr WP9 | A182 Gr F9 | A217 Gr C12 | ||

| Carbon Steel Alloy Low-Temp | A420 Gr WPL6 | A350 Gr LF2 | A352 Gr LCB | A320 Gr L7 A194 Gr 7 |

| A420 Gr WPL3 | A350 Gr LF3 | A352 Gr LC3 | ||

| Austenitic Stainless Steel | A403 Gr WP304 | A182 Gr F304 | A182 Gr F304 | A193 Gr B8 A194 Gr 8 |

| A403 Gr WP316 | A182 Gr F316 | A182 Gr F316 | ||

| A403 Gr WP321 | A182 Gr F321 | A182 Gr F321 | ||

| A403 Gr WP347 | A182 Gr F347 | A182 Gr F347 |

ASTM standards define the specific manufacturing process of the material and determine the exact chemical composition of pipes, fittings and flanges, through percentages of the permitted quantities of carbon, magnesium, nickel, etc., and are indicated by "Grade".

The usual materials of flanges include stainless steel, carbon steel, aluminum and plastic. The choice of the material largely depends on the purpose of the flange. For example, stainless steel is more durable and is necessary for heavy use. On the other hand, plastic is more feasible for use in the home because of its reasonable price and easy installation. The materials used for flanges are under the designation of the American Society of Mechanical Engineers.

Flange materials acc. to ASTM

The most common materials for pipe flanges (forged grades) are: ASTM A105 (carbon steel high temperature to match A53/A106/API 5L pipes), A350 Grades LF1/2/3 (carbon steel low temperature to match A333 pipes), A694 Grades F42 to F80 (high yield carbon steel to match API 5L pipe grades), ASTM A182 Grades F5 to F91 (alloy steel flanges to match A335 pipes), A182 Grade F304/316 (stainless steel flanges to match A312 SS pipes), A182 Gr. F44/F51/F53/F55 (duplex and super duplex to match A790/A928 pipes) and various nickel alloy grades (Inconel, Incoloy, Hastelloy, Monel).

The material qualities for these flanges are defined in the ASTM standards.

What are ASTM Grades?

For example, a carbon steel pipe can be identified with Grade A or B, a stainless-steel pipe with Grade TP304 or Grade TP321, a carbon steel fitting with Grade WPB etc.

Standard

Pipe Flange Standards mainly include three systems in the world, ANSI/ASME flange system(American), DIN flange system(European system), JIS flange system, other system made according to this three systems, like GB flange standard, which mainly made according to ANSI/ASME and DIN flange standard, Duwa Piping supplies those flanges with top quality and soonest delivery time.

ASME standards

- ASME B16.1 - Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250

- ASME B16.5 - Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard

- ASME B16.20 - Ring Joint Gaskets and Grooves for Steel Pipe Flanges

- ASME B16.21 - Nonmetallic Flat Gaskets for Pipe Flanges

- ASME B16.24 - Cast Copper Alloy Pipe Flanges and Flanged Fittings: Classes 150, 300, 600, 900, 1500, and 2500

- ASME B16.34 - Large Diameter Steel Flanges (NPS 26 through NPS 60)

- ASME B16.36 - Orifice Flanges

- ASME B16.42 - Ductile Iron Pipe Flanges and Flanged Fittings: Classes 150 and 300

- ASME B16.47 - Large Diameter Steel Flanges (NPS 26 Through NPS 60)

ASTM standards

- ASTM A105 - Specification for Carbon Steel Forgings for Piping Applications

- ASTM A182 - Specification for Forged or Rolled Alloy Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High Temperature Service

- ASTM A193 - Specification for Alloy Steel and Stainless Steel Bolting Materials for High Temperature Service

- ASTM A194 - Specification for Carbon and Alloy Steel Nuts for Bolts for High Pressure and High Temperature Service

- ASTM A694 - Specification for Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service

- ASTM A707 - Specification for Flanges, Forged, Carbon and Allow Steel for Low Temperature Service

AWWA standards

- AWWA C115 - Standard for Flanged Ductile Iron Pipe with Ductile-Iron or Gray-Iron Threaded Flanges

ISO standards

- ISO 5251 - Stainless steel butt-welding fittings

MSS standards

- MSS SP-6 - Standard Finishes for Contact Faces Pipe Flanges and Connecting End Flanges of Valves and Fittings

- MSS SP-9 - Spot Facing for Bronze, Iron and Steel Flanges

- MSS SP-25 - Standard Marking Systems for Valves, Fittings, Flanges, and Unions

- MSS SP-44 - Steel Pipeline Flanges

- MSS SP-53 - Quality Standards for Steel Castings and Forgings for Valves, Flanges and Fittings and Other Piping Components - Magnetic Particle

- MSS SP-54 - Quality Standards for Steel Castings and for Valves, Flanges and Fittings and Other Piping Components - Radiographic

- MSS SP-55 - Quality Standards for Steel Castings and for Valves, Flanges and Fittings and Other Piping Components - Visual

- MSS SP-75 - High Test Wrought Butt Welding Fittings

- MSS SP-106 - Cast Copper Alloy Flanges and Flanged Fittings Class 125,150, and 300

- ASME B16.5 and ASME B16.47 cover pipe flanges up to NPS 60 (B16.5 from 1/2″ to 24″ and B16.47 from 26″ to 60″). ANSI

- B16.47 covers two series of flanges, Series A is equal to MSS SP-44-44, and Series B is equal to API 605 (API 605 has been canclled).

Flange material standards

Flanges are used to connect pipes or other equipment components in various industries, and they come in a variety of materials and sizes. Flange material standards are developed by standard-setting organizations and describe the properties and characteristics of different materials that can be used to make flanges. Some examples of commonly used flange material standards include:

- ASTM A105: This standard covers forged carbon steel piping components, including flanges, that are suitable for use in high-pressure applications.

- ASTM A182: This standard covers forged or rolled alloy steel pipe flanges, forged fittings, and valves and parts intended for high-temperature service.

- ANSI B16.5: This standard specifies the dimensions, tolerances, and markings for steel pipe flanges and flanged fittings.

- DIN 2632-2638: This standard defines the dimensions and tolerances for flanges made from steel, including carbon steel, stainless steel, and other alloys.

- ASME B16.47: This standard covers large diameter steel flanges, typically used in high-pressure applications where larger bore sizes are needed.

- BS 4504: This British standard covers circular flanges for pipes, valves, and fittings, with nominal sizes ranging from 15 to 600 mm.

The choice of flange material standard will depend on various factors such as the application, the environment, the fluid being transported, and the required performance characteristics. For example, high-pressure applications may require flanges made from materials with high strength and durability, while corrosive environments may require flanges made from materials with good resistance to corrosion.

FAQs

The most frequently asked questions regarding flanges and flange fittings have to do with how flanges fit on specific steel tube and steel pipe ends.

How flanges operate?

Flanges have flat or flush surfaces that are vertical to the pipe to which they are attached. The attachment process involves mechanically joining two or more faces using bolts, adhesives, collars, or welds. Due to the attachment requirements, a flange must fit the equipment or pipe that it's designed. That's why it's necessary to check all the possible specifications and dimensions to ascertain that it's of the right size, type, and material.

What are the three parts of a flanged connection?

Pipe flanges, gaskets, and bolts are the three parts that comprise a flanged connection. Gaskets and bolts are typically made of the same flange materials or a material approved for the pipe components. Each component comes in various materials that suit specific applications and must be matched correctly for proper functioning. The gaskets come in two conventional types: full-face gaskets and ring gaskets. Full-face gaskets have the bolt holes visible and pair up with raised-face gaskets. Ring gaskets tend to be smaller rings minus the bolt holes and pair up with flat-faced flanges. Securing the flange components requires matching the surfaces evenly and plumb, adjusting as needed for a uniform fit. Once all surfaces match, bring the flanges together and secure at least two of the bolts. Refine the alignment, so the remaining bolt holes match and their corresponding bolts are tightly secured.

How do I properly size a flange for pipe use?

Properly sizing a flange for pipe use depends not only on the type of flange but its compatible piping. The pipe must slip into the flange's inside diameter easily and securely, and the outside diameter should cover wall holes. Once you determine the specific flange type and material you need for the job, you'll need to take several measurements. The four measurements you'll need are the inside diameter, outside diameter, bolt hole count, and bolt hole center. You'll need to align each of these measurements from opposing bolt holes to get the most accurate readings. Take all measurements from edge to edge and try to get as precise as possible to match the correct product. Round up bolt diameter to the next half or whole step since bolts measure half or whole inches. Once you have all four measurements, check them against the manufacturer's table to find the correct flange. Most manufacturers list these specifications on their websites for easy reference.

Flange Inspection

Before dispatching from manufacture each flange is inspected to ensure quality. During an inspection you have to check the following;

- Outer & Inner Diameter of body

- Bolt Circle & Bolt hole Diameter

- Hub Diameter & thickness of weld end

- Length of the Hub

- Straightness and alignment of the bolt hole

ASME B16.5 and B16.47 standards cover permissible tolerances for inspection.

Packing

Because of the normal wooden boxes or wooden pallets have to do fumigation treatment, we usually use plywood pallet or plywood case or box to pack steel flanges without fumigation treatment.

Flanges Applications

A flange is a method of connecting pipes, valves, pumps, and other equipment to form a piping system. It also provides easy access for cleaning, inspection, or modification.

When a piping joint requires to be dismantled, flanges are being used. These are primarily used on equipment, valves, and specialty items. Breakout flanges are provided at predetermined intervals in certain pipelines where maintenance is a regular occurrence. The flanges, gaskets, and bolting make up a flanged joint, which is made up of three separate but interconnected components. To achieve a leak-proof joint, special controls are required in the selection and application of all of these elements.

Here are the details of Flanges about their advantages and their applications.

Our Contact